| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : JERO

Model Number : JA26

Certification : IATF 16949 IRIS CE ISO NADCAP

Place of Origin : HENAN, CHINA

MOQ : 7 TONS

Price : US$3500-3800 Per Ton

Payment Terms : L/C,T/T,Western Union,MoneyGram

Supply Ability : 3000 TONS PER MONTH

Delivery Time : 20-30 working days

Packaging Details : Seaworthy Export Package

Type : Aluminum alloy coil

Thickness : 0.8-6mm

Alloy : 3003/5052/5083

Temper : H14/H32 etc

Surface : Anodizing/PVDF coating

Trade terms : CIF,CNF,FOB,EXW

2500mm Width Aluminum Alloy Coil Used For Chemical Linings

Aluminum coils are optimally suited for large chemical tank linings due to their proven

corrosion resistance, lightweight yet strong construction,cost-effective lifecycle performance

adaptability to mega-scale projects

Common Alloys & Tempers

Alloy Selection:

♦ 5052 (Al-Mg series): Excellent corrosion resistance for weak acid/alkali environments

(e.g., petrochemical storage tanks).

♦ 3003 (Al-Mn series): Resists general chemical media; cost-effective (non-aggressive environments).

♦ 6061 (Al-Mg-Si series): High strength with T6 heat treatment; suitable for structural linings.

♦ 1100 (Pure aluminum): High corrosion resistance but low strength; used for non-pressure linings.

Tempers:

H32/H34 (5052/3003): Half-hard, balances strength and formability.

T6 (6061): Age-hardened for high-stress applications.

Recommended Thickness Range

♦ 0.5–1.5mm: Light-duty linings (pipes, small containers).

♦ 1.5–3.0mm (Most common): Tanks, reactor linings (corrosion + mechanical resistance).

♦ 3.0–6.0mm: Heavy-duty equipment (pickling tanks, pressure vessels); requires welding/bolting.

| Thickness Range | Application Scenario | Typical Configuration |

| 0.5-1.5mm | Pipeline linings | 3003-H14 + PVDF coating |

| 1.5-3.0mm | Storage tank linings | 5052-H32 + Anodizing |

| 3.0-6.0mm | Reaction vessels | 5083-H321 + PTFE laminate |

Key Advantages

Corrosion Resistance

Natural oxide film resists acids/alkalis/salt spray (5052 performs best at pH 4–9).

Outperforms carbon steel; can replace stainless steel in mild sulfuric acid.

Lightweight

1/3 the density of steel, reducing structural load.

Workability

Easily coiled, welded (with shielding gas), or riveted for complex geometries.

Our Company Advantages

Technological & Production Strengths:

R&D Capabilities: Own a national-level corporate technology center and contributes to industry

standards.

Production Scale: We had an annual capacity exceeding 1 million tons of aluminium large-scale

rolling mills.

Production Ability: We can produce the great Aluminum material for automobile, railway transportation,

marine, aerospace etc fields, and obtained the relevant certification.

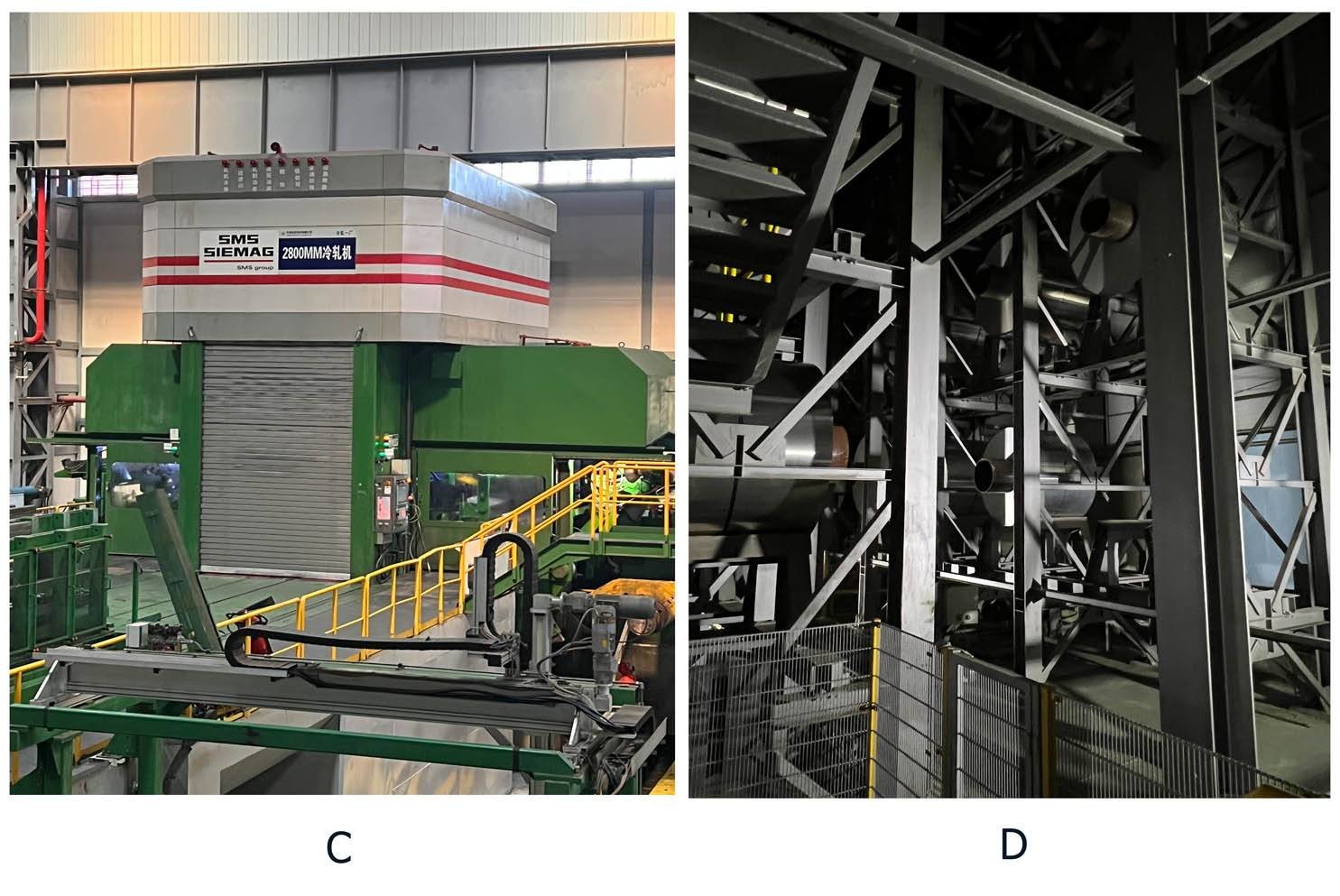

Our factory own the world advanced equipments, include:

| Code | Name | Brand |

| A | aluminum ignot melting furnace | GAUTSCHI (Switzerland) |

| B | 4 continuous hot rolling mills | SMS Group (Germany) |

| C | 2800mm width single stand cold rolling mill | SMS Group (Germany) |

| D | all automatic three-dimensional elevated warehouse | Dematic (USA) |

|

|

2500mm Width Aluminum Alloy Coil For Chemical Linings Images |